ZhuZhou Gold Sword Cemented Carbide Co., LTD.

ZhuZhou GoldSword Cemented Carbide Co.,LTD a rapid grow company

expertise and professional in carbide materials and carbide cutting

tools over 20 years of experience,integarated with new

technology,high-end machinery and collaborated with researcher and

university to enhance the cutting tool maker to make good quality

tools for customer to reduce their cost gain more market share with

us.

The company has advanced equipment a wide range of inspection

equipment's to fulfil products quality inspection, using ERP system

for production management and ordering processing , tracking and

delivery, The company mission and vision are to help customer to

reduce their cost and gain more market share with us.

Main products

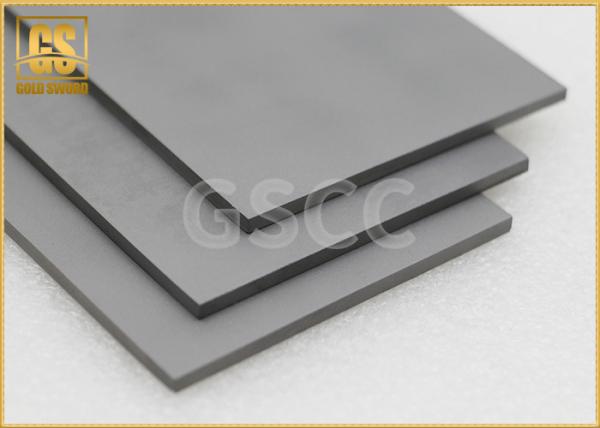

carbide strips, carbide STB bars, carbide sand breaking strips,

carbide ASA brazing tips, carbide cold heading dies and carbide

rods, carbide cutting, carbide end mill carbide drill,carbide taps,

wood working tool, wood cutting insert, carbide drill

bit saw blade and planer, planer reversible cutting insert carbide

saw tips, solid carbide rod for metal & wood, advertising working

tools, tungsten carbide perform tools like strips plate block.

Pressing Workshop

Sintering workshop 1

Sintering workshop 2

Processing workshop

Surface treatment workshop

Finishing workshop